|

|

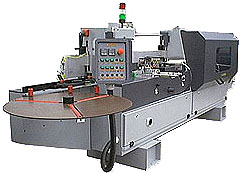

| The Y series offers a complete line of models for

applying every type of edge, from roll material to solid wood, up

to 15 mm of thickness, on panels of varying thickness from 10 to 60

mm.

This series’ modular design allows user to customize the machine, choosing between working units, for specific production needs. |

|

|

Y 3010 |

Y 4010 |

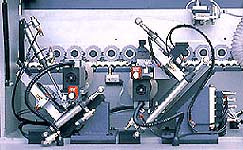

| The Y series “R” version is equipped with RECTIFYING UNIT. The unit rectifies panel sides before edge banding , removing from 0 to 1 mm of material. Equipped with cutters featuring opposite rotation in order to avoid chipping and obtain a perfect finishing. Choose between throw-away cutters or diamond cutters. |

|

STANDARD EQUIPMENT

ACCESSORIES ON REQUEST

|

| OPERATION UNITS | ||

|

|

|

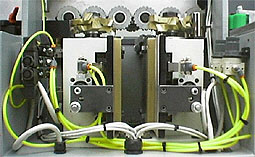

| Overlapped

Trimming Unit The unit trims top and bottom surplus of edges, using flat edge cutters. High quality workmanship with easy to adjust height sensors, thanks to numerical indicators. |

Rounding

off Unit Finishes the front and back lower corners of edges applied on postformed panels. Equipped with 3 mm radius edge cutters and numerical indicators for easy adjustments. |

|

|

|

|

| Multi-Function

Unit This unit is designed to finish front and back, upper and lower corners of edges applied on postformed panels, but it can also be used with other working operations like trimming of top and bottom edges. The processing changes are carried out from control panel. |

Scraping

Unit Performs a perfect finishing of PVC and ABS edges, taking away any imperfections produced by the Trimming Unit. The unit works as an Edge-Scraper, when using the curved edge of the tools, but can also work as a Glue-Scraper, removing any glue residuals, when using the flat edge of the tools. Fast processing changes, thanks to numerical indicators. |

|

|

|

|

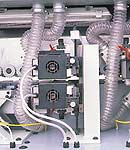

| Polishing

Unit The unit allows for a perfect cleaning and buffing of PVC and ABS edges. Equipped with brushes of a resistant cloth, and can be adjusted both in height and depth. |

Molding

Unit Carries out millings on the edged side or on the top and bottom sides of the panel. Tiltable to 90°, can be cut out from the working cycle by means of a dual switch on the control panel. |

|

| Sanding

Unit It sands veneer edges or rigid wooden strips, featuring vertical alternate moving. Equipped with numerical indicator for easy adjustments and dual switch on the control panel for its automatic cutting out. |

Hot

Air Jet It warms PVC and ABS edges. |

|

Y MAS 20 To complete the range of edge banding machines, we have designed Y MAS 20, suitable for working with solid wood, up to 20 mm of thickness. As for the other models of Y series, the Y MAS 20 can also be customized according to specific production needs. |

The main features

are:

|